Optical mirrors are at the forefront of innovation, driving advancements in industries ranging from healthcare and telecommunications to aerospace and defense. With the demand for precision optics growing, the development of cutting-edge technologies and customized solutions has become a central focus. This article explores the latest trends in optical mirrors, including key developments in materials, manufacturing, and customization, alongside relevant industry statistics.

The Rise Of Customized Optical Solutions

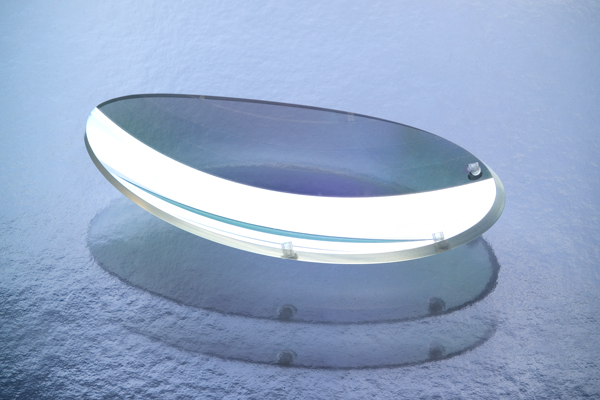

A significant trend in the optical mirror market is the shift toward customization. As industries seek highly specific optical components, the demand for custom aspheric lenses and mirrors is on the rise. Unlike traditional spherical lenses, aspheric lenses offer superior performance by minimizing aberrations and ensuring precise light focusing. These features make them indispensable for applications like high-resolution imaging, laser systems, and advanced optical instruments.

Custom optical mirrors, including aspheric designs, are tailored to meet unique specifications for industries requiring exceptional accuracy. For example, in aerospace applications, where even minor distortions can result in significant errors, custom mirrors ensure unparalleled precision. Similarly, in medical devices such as endoscopes, customized optics enhance image quality, aiding accurate diagnosis and treatment.

Material Innovations In Optical Mirrors

Material selection has always been a cornerstone of optical mirror performance. Recent advancements in materials like fused silica, borosilicate glass, and specialized coatings have led to mirrors with enhanced reflectivity, durability, and resistance to environmental factors. Dielectric coatings, for instance, provide exceptional reflectivity for specific wavelengths, making them ideal for laser systems and high-energy applications.

Furthermore, lightweight materials such as carbon fiber-reinforced composites are gaining traction, particularly in aerospace and satellite systems. These materials reduce the overall weight of optical systems, improving efficiency without compromising performance.

How Are Optical Lenses Made?

The manufacturing process of optical lenses, including mirrors, has undergone significant advancements to meet the demand for precision and scalability. Typically, the process begins with selecting high-quality optical glass or plastic materials, which are then shaped using grinding and polishing techniques. Modern computer-controlled machinery ensures that lenses and mirrors achieve the exact curvature and surface quality required.

The coating is a critical step in the production process, where reflective or anti-reflective layers are applied to enhance optical performance. For custom aspheric lenses, advanced methods like precision molding or diamond turning are employed to achieve the desired aspheric shape. These innovations ensure that every optical component meets the stringent requirements of its intended application.

As manufacturing processes continue to evolve, answering the question “How are Optical Lenses Made?” reveals a world of innovation dedicated to meeting the growing demand for precision and performance.

Industry Trends And Applications

Miniaturization of Optical Systems

As industries lean toward compact and portable technologies, optical mirrors and lenses are being designed to fit smaller systems without compromising performance. This trend is especially prominent in consumer electronics, where miniaturized cameras and sensors require advanced optics.

High-Performance Coatings

Coatings are pivotal in defining the performance of optical mirrors. Anti-reflective, dichroic, and metallic coatings are evolving to enhance light transmission, reduce glare, and improve reflectivity. This trend is critical for high-energy lasers and telescopes.

Sustainability and Eco-Friendly Manufacturing

With a growing emphasis on sustainability, manufacturers are adopting eco-friendly processes and materials. For instance, reducing the use of toxic chemicals in coating applications and recycling optical materials are gaining importance in the industry.

Integration with Smart Systems

Optical mirrors are increasingly integrated into smart systems for automation and artificial intelligence applications. In robotics and autonomous vehicles, these mirrors enable precise light manipulation for sensors and imaging systems.

Market Statistics

According to research, the global market for optical mirrors is anticipated to expand at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This growth is driven by the rising demand for advanced optics in industries such as healthcare, electronics, and defense. The market for custom aspheric lenses is also expanding, expected to reach $2.5 billion by 2030, underscoring the importance of tailored optical solutions.

Conclusion

Optical mirrors are a cornerstone of technological advancement, with trends like customization, material innovation, and eco-friendly manufacturing driving the industry forward. Custom aspheric lenses, in particular, are revolutionizing the market by offering superior precision for high-tech applications. With the market poised for significant growth, optical mirrors will remain integral to progress in diverse sectors.